|

Building the Tom Henry RS

Part

4: Suspension Mods, Tires, Wheels, Headers and other

Cool Stuff.

by Hib Halverson

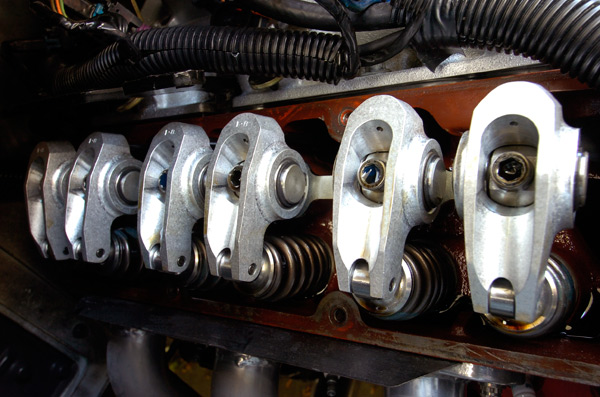

At the end of Part

Three, we changed the valvetrain of the 3.8-liter V6 in

the Tom Henry RS. We installed new, Yella Terra

"Ultralite" 1.8:1, aluminum roller rocker arms, Katech

valve springs and Katech titanium retainers on our 3800

Series II V6.

Ultralites are nearly

25% lighter than the stock 1.6 rockers and 8% lighter

than the SLP aluminum rockers we took off. What's even

better about the new Yella Terra rockers is from where

in the rocker the weight was removed. It was mainly

taken from the valve end where mass reduction would have

more impact. The Katech springs (PN PSI-LS1511) have a

little more pressure than the Comp springs in the motor

previously and the Katech "ti" retainers (PN KAT-4678)

are a little lighter than the Comp retainers we took

off.

|

|

|

These parts saved us from

the valve float problems we experienced

during previous parts of this project.

At one time we were unable to get the

engine to run hard above 5700 rpm or so

because of that. A little less

valvetrain mass in the Yella Terra

Ultralite rockers and Katech titanium

retainers and a little more spring

pressure from Katech valve springs and

the valve float was eliminated. The

engine pulls safely to it's 6200 rpm rev

limiter. Image: CHpg Staff. |

Less valve train mass

and a little more spring pressure was the remedy for a

valve float problem we experienced when running the

engine over 5800 rpm. Before we went back to the dyno to

validate that theory, we wanted to get some drive time

on the new parts. We, also, wanted to have some headers

made for the car. Finally, we wanted to perform some

more suspension mods and add a few "safety" features.

|

A goal of this project was to have a 250-hp engine and

pass an exhaust emissions test–not just any old

"sniffer" test, either. It had to be the stringent

"Enhanced Smog Check" required in the State of

California's urban areas. Similar tests may be required

in a few other states. We took the Camaro to Quality

Auto Service in Pomona, California to see if the engine

would pass with the modifications to date. Owner, Mike

Garibay, is well-versed in emissions testing and service

work. His shop is one of our favorite general repair

facilities because of its good customer service.

The Enhanced test combines inspection of

emissions parts with an exhaust gas test taken

while the car runs on a moderately-loaded

chassis dyno at both 15 and 25 mph. We easily

passed the test. In fact, Garibay commented that

he didn't see very many mod'ed cars that ran so

clean. |

|

|

|

Mike Garibay readies our

car for Smog Checking by inserting the

"sniffer" in our Flowmaster exhaust.

Image: CHpg Staff. |

|

Suspension, Wheels,

Tires

The Tom Henry RS's rear

suspension felt, well... "sloppy" is the best way we can

describe it, in accel/decel transitions, during quick

shifts at wide-open-throttle or on roads were slab

joints or tar strips get the suspension hopping. This is

caused by the soft rubber mount GM stuck on the end of

the rear axle torque beam along with the weak-suck,

stamped-steel beam flexing under load. Another problem?

During hard acceleration, drive torque acts on the

beam's length to decrease rear tire loading. This

reduces traction, both in a straight line and

accelerating out of corners. Lastly, when you lower a

3rd or 4th Gen Camaro, traction degrades even more due

to decreased anti-squat caused by the change in rear

suspension geometry.

Popular with

autocrossers, road racers and drag racers is Global West

Suspension's "TracLink" assembly (PN TSC-23). It alters

rear geometry such that its leverage point moves to a

more optimum location.

Drive-torque-induced tire loading changes from negative

to positive improving traction

during acceleration, both straight line and out of

turns. What's more, TracLink eliminates wheel hop and

has a pinion angle adjustment. Finally, of interest to

drag racers required to add a driveshaft loop, the

mounting points for that are built into the TracLink.

|

|

|

Global West's owner, Doug Norrdin, and

an assistant, installed the TracLink (PN TSC-23) in a

few hours using a drill and common hand tools. For the

complete photo sequence showing how to install a

TracLink,

click here.

Image: CHpg Staff.

|

Global West markets

this product mainly for V8 cars, but the kit for a 3rd

Gen V8/automatic Camaro, also, fits a 4th Gen V6. The

installation requires removal of the left rear seat

cushion, drilling some holes in the left rear seat well

and one hole in the transmission mount crossmember.

Other than that, TracLink is a bolt-on for all 4th Gens.

|

|

|

The Global West

Anti-Squat Bracket kit for 82-02

Camaros. Image: CHpg Staff. |

|

Like some racing-derived performance enhancements,

this one has compromises for road cars. When it comes to

noise, TracLink is not for

the faint-hearted because, since it

dispenses with the large rubber isolator at the front

end of the torque beam, powertrain noise

and

vibration in the interior increases. We totally want the

Global West TracLink's positive affect on acceleration

and handing, so we'll take the noise, however, those

expecting Camaros with modified suspensions to have

interior noise-and-vibes levels the same as or close to

stock should carefully consider this product. |

|

The TracLink installation was done by Global West's

technicians at its factory in San Bernardino, California

and included the addition of "Rear Anti-Squat Brackets"

(PN VTC-27). These brackets must be welded to the rear

axle housing. Once in place, they compliment the

TracLink by further improving traction exiting turns.

Additionally, they are ideal for a lowered car because

they further alter rear suspension geometry such that

its instantaneous center moves to a point more

appropriate when ride height is reduced. That

change increases the rear suspension's percentage of

anti-squat such that that car tends to hook better

during hard acceleration.

Lastly, these brackets have two positions for

the rear control arm pivots allowing drag racers

to adjust the car's bite for track conditions or

changes in ride height. With the TracLink and

Anti-Squat Bracket installations complete, we

bid all the good people at Global West farewell

and headed back to our shop. |

|

|

|

Like most of Global's

suspension parts, the Anti-Squat

Brackets are black powder coated.

Because the brackets must be welded in

place, the coating must be removed in

the places where welding will take

place. Here, Global's Eric Norrdin uses

an abrasive disc to do that. For a photo

sequence showing how to install these

brackets,

click here.

Image: CHpg Staff |

|

We wanted more

radical tires and wheels, so we swapped the 245/50ZR16

Goodyear Eagle F1 GS-D3s on stock, 8" wheels we'd been

using up to now for a set of 265/40ZR17 Eagle F1

Supercars on 9.5" Fikse Profil 5Ses. We should add that

the F1 GS-D3s were on the car for several years

providing good dry and wet traction and outstanding

tread life on a car that gets driven pretty hard.

|

|

|

The Fikse Profil 5S is a

forged-aluminum masterpiece. Each is

assembled with aerospace fasteners and

is serialized to facilitate quality

control and help verify ownership

of–heaven forbid–a stolen wheel. Image:

Paul Conrath/Fikse USA. |

|

The Fikse (it's "fick-sea" not "fis-ski", by the way)

Profils are awesome-looking wheels. Because Fikses are

so light for a street wheel, we could go from a 16x8 to

a 17x9.5 yet not increase unsprung weight, but we

expected this, considering their racing pedigree–cars on

Fikses have won both the World's preeminent endurance

races, the 24 Hours of Daytona (4 times!) and the 24

Hours of LeMans.

The Fikse Profil 5S is a modular design with a

rotary-forged, CNC-machined, clear powder-coated,

aluminum center. The rims are forged, heat-treated

aluminum. "TechniPolish" is Fikse‘s standard finish and

features a robust, liquid-cured clearcoat on the

diamond-turned center section. The mirror-polished rims

are left polished and uncoated to allow for touch-ups as

needed in case of minor scrapes.

|

|

While brothers Matt and

Jim Fikse (yep, it's a family operation with their name

on the building) couldn't share specific manufacturing

secrets with us, they did reveal that, unlike most wheel

companies, Fikse USA manufactures its own centers and

rim halves. Having done that since 1992, makes Fikse one

of the few companies in the U.S. that controls the

wheel-making process from start to finish. Doing that

enables it to maintain a high level of quality few

manufacturers can equal and none exceed. Fikse builds

4th Gen. Camaro wheels in two offsets, 38mm and 51mm. We

chose the 38s because they slightly widen the car's

track for a better look.

Needless to say, Fikses

are not cheap, so wheel locks are manditory to deter

theft. Initially, we reused the stock Camaro wheel locks

but they didn't look very good. The Profils come with

high-quality, McGard wheel nuts so we went looking for a

set of McGard's locks, figuring they'd better match the

nuts' appearance.

|

|

|

|

Each of these wheels

weighs about as much as the stock 16x8s

they're replacing, in-spite of being

larger in diameter and wider. Image:

CHpg Staff. |

|

|

|

|

To protect high-end

wheels, you want experienced tire

specialists, like Tucker Tire's Bernie

Berthet, mounting your tires. Fikses

require specialized mounting procedures

and Tucker provided that service. Image:

CHpg Staff. |

|

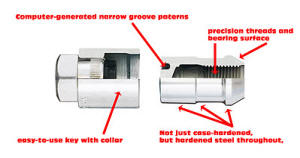

McGard makes perhaps

the best wheel lock in the industry. They're made of

hardened steel...not just "case-hardened," but

hardened throughout and tempered. Like most locks,

they require a special "key tool" and the design of the

key and the pattern in the lock allow a virtually

unlimited number of computer-generated combinations.

To install or remove

the lock, the key's collar, aligns the key to the lock.

All you need to is gently push the key over the lock

then turn the key until the patterns engage. McGard

locks are nickel-chrome plated. Basically, these locks

will probably outlast the car. The simple function,

outstanding security and excellent durability of the

McGard design might be why they're OE on some 30 car

lines, worldwide.

|

|

|

|

Image: McGard, LLC. |

|

|

What makes the McGard

locks easy to use is the key's locating

collar. You just gently push it on the

lock and turn until it engages. The

locks, themselves, look much better on

our Fikses than did the OE GM locks.

|

|

Jumping from the F1

GS-D3 to Goodyear's ultimate, dry traction tire, the

wider, more grippy, F1 Supercar; improved straight line

bite, cornering power and steering response. The

Supercar, in 265/40ZR17, was originally developed for

the C5 Corvette Z06 and is one of only a few tires which

bridges the gap between all-round, ultraperformance

tires, such as the "D3", and DOT-approved, radial road

race tires which are not acceptable for general street

use because of short tread life and almost nonexistent,

wet traction. While the F1 Supercar is more sticky than

what we took off, admittedly it's not the drag race tire

that a "drag radial" from Goodrich, Nitto or Goodyear

might be. Perhaps we'll try one of them in the future.

The main advantages to

the Tom Henry RS with the F1 Supercars are improved

at-limit handling due to more traction coming from a

wider tread, more aggressive rubber compound and a tread

block design skewed towards handling. Additionally, the

F1 Supercar casing is designed to improve steering feel

and response. |

|

Where the Supercar

gives-up a little to the F1 GS-D3 is in 1) wet

traction--the D3's tread design is superior when it comes

to channeling water away from the contact patch 2) tread

life--because the Supercar has softer rubber and more

shallow grooves--and 3) noise and harshness.

We hauled the Fikses

and Goodyears over to Covina, California's Tucker Tire

Service Co, where they were mounted and balanced. On

return to our shop, we stuck the THRS up on jacks and

swapped the tires and wheels then torqued the McGard

nuts and locks. Man...those Fikses and F1 Supercars are

just so damn pretty!

|

|

|

|

The Tom Henry RS on Fikses and F1

Supercars. The Goodyears really grip by virtue of very

rigid blocks on the outside of the tread and shallow

tread depth. Image: CHpg Staff.

|

|

Rollback Blues

After a month or so

running the new valvetrain pieces, we decided to check

how modifications to date affected the car's 1/4-mile

performance. We often acquire acceleration data using a

Vericom Performance Computer, a benchmark for

medium-priced, self-contained, vehicle dynamics testers.

These units are used by government agencies, vehicle

manufacturers, tire companies, independent testing

facilities and discriminating car enthusiasts needing

accurate vehicle dynamics data from an on-board device.

The Vericom VC3000 has a two-axis accelerometer core,

400Hz sampling rate, and ability to upload data to a PC

via a USB port. It displays data on a 128x64 LCD screen,

can recall up to 256 tests from memory and–we saved the

best for last–with the DAQ model, ability to record

engine controls data via the car's diagnostic link

connector (DLC) as well as from up to six optional

sensors.

We installed the

VC3000DAQ, then headed for our back-road testing venue,

but in a "reality bites" moment, part-way there; the car

quit. We came back to the shop riding in a

Freightliner rollback with our wallet 120 bucks lighter.

|

|

|

The Vericom VC3000's

large display and improved keyboard make

it nicer to use. The built-in bubble

levels make mounting and leveling the

Vericom before use quite easy. Image:

Vericom Computers. |

|

Some failure caused by

our mods? Hardly!

After doing the "cranks

but won't run" diagnosis in the Camaro Service Manual,

we figured the fuel pump was bad. We pulled the

exhaust–potentially a nightmare job made easier with

Eastwood's "EZ-Pull" exhaust joint separating tool (PN

43583)–drained the fuel, got the gas tank out, pulled

the pump "bucket" and bench-tested it.

|

The pump was stock,

went 58,087 miles and...was deader than a freakin' door

nail. Sheesh! So much for GM fuel pump durability. We

emailed Racetronix and ordered its High Performance Fuel

Pump System (PN F99-FPKG-2).

We had to make use of

the downtime while we waited for the Racetronix parts to

arrive, so we worked on changes to the car which would

improve safety when driving at higher speeds in wet

weather or at night.

Believe it or not, it

does rain in Southern California and a few storms late

last winter had us trying Super Silicone wiper blades

(PN 93060) from WeatherTech Auto Accessories. Made for

WeatherTech by PIAA from "activated" silicone rubber, as

the blade wipes; it leaves a slight residue which builds

over time, causing water to bead making the wiper's job

easier. Silicone WeatherTechs are more durable than

typical rubber units, too, so they hold a sharp edge

longer.

|

The THRS needed better headlights–not cute, blue bulbs,

either. We wanted lighting which works, so we installed

Harrison-Toshiba, Halogen Infrared Reflective (HIR)

bulbs (PNs 9011, 9012) from Daniel Stern Lighting, a

performance lighting components distributor. Not

"over-wattage", blue-tinted stockers, Harrison-Toshiba

bulbs' critical dimensions are the same as O.E., so they

fit right into the stock Camaro light assemblies. They

use HIR technology which eliminates the short life,

greater heat production and higher current draw of

over-wattage bulbs. Their power consumption is the same

as stock, yet the low beam produces 87% more light and

the high-beam, 50% more light. Stern's HIRs enhanced our

nighttime driving safety. |

|

|

|

A Harrison-Toshiba

Halogen Infrared Reflective (HIR) bulb

(left), is reminiscent of an

old-fashioned light "globe," but that's

where similarity ends. An

optically-transparent coating on the

inside of that spherical section

reflects infrared radiation back at the

filament, making it hotter so it

produces more light than it can by

current flow, alone. Image: CHpg Staff |

|

|

|

|

An HIR bulb (right) must

be modified by trimming the tab in the

areas shown inside the arrows. The

resulting tab is shorter and more

narrow. Trimming is easy with a pair of

wire cutters. Image: CHpg Staff |

The Tool Man Cometh

|

|

|

Buying the Mac Edge

ratcheting wrenches was sort of a

"well...duh" moment for us. Once we

started using them, we couldn't

understand how we lived without them.

Image: CHpg Staff. |

|

About the time we

finished the headlight bulb installation, our Mac Tools

truck stopped out in front–perfect on a day which was

slow out in the shop and the day after pay day. We spent

some more money with the Mac man and acquired additional

tools to make our project less tedious. Ratcheting

combination wrenches are the rage these days and we'd

been slow to get hip to that sitch, but not any longer.

From Mac Tools, we picked up two sets of them for SAE

(PN SRW27K) and metric (PN SRWM212K) fasteners.

These wrenches are in the "Mac Edge" line, all of which

use some unique "socket" technology which makes using a

combination wrench use easier. |

We

bought Mac Tool's "Zero" ratchets in 3/8-drive (PN

XR8PAZ) and 1/4-drive Flex Head (PN MR7PAZF). Several

tool makers have ratchets with as little as 5° lash,

however, the lower lash mechanism makes a weaker tool.

The Zero uses a cam and roller-bearing assembly–like a

sprag in an automatic trans–so it has no lash. This

makes for easier use in tight spots, but also, a strong,

durable tool.

|

|

|

After using these Mac

Tools "Zero" ratchets for a while we

like the soft rubber handles more than

the zero-lash feature. Image: CHpg

Staff. |

|

|

|

|

Since some of the screw

drivers in the shop are kinda ratty and

others have "disappeared," a new set was

in order. We appreciate Mac's

comfortable handles and, well...we have

a thing for purple. Image: CHpg Staff. |

|

|

The original thermal insulation on the engine's

fuel hoses needed replacement and we wanted to

insulate other fuel system parts near the

engine, too. We cut the tattered O.E. stuff away

and replaced it with Design Engineering's Heat

Sheath (PN 010419), using longer lengths to

insulate more of the hoses. We used DEI Cool

Tape (PN 010413) to bond the Sheaths to the

hoses. We cut a 7x10" square of DEI Floor and

Tunnel Shield (PN 050503) to cover the ends of

the hard fuel lines adjacent to the left exhaust

manifold. All this was to keep the fuel cooler.

More Cool Tape repaired insulation on crankshaft

and camshaft position sensor wiring where it

passes through a very hot area adjacent to the

EGR valve. Lastly, in preparation for our header

installation, we added DEI Protect-a-Boots to

our MSD plug wires.

|

|

|

|

The stock fuel lines are

wrapped in insulating sheath over a

length of them routed above the left

exhaust manifold. The original sheath

was pretty ratty so we replaced it.

Image: CHpg Staff. |

|

|

|

|

Design Engineering's

Heat Sheath is generally the same as

what GM wrapped on fuel hoses at the

factory. We added additional heat

reflective material to shield the fuel

lines which run along the left subframe

rail adjacent to the left exhaust

manifold. Image: CHpg Staff |

|

To date, since the THRS is also a daily driver,

we racked-up a lot of miles doing this project,

so it was time for an oil change. We drained the

oil, changed filters–we use the LT1 V8's larger,

PF52–then poured-in five quarts of Red Line

10W30 synthetic engine oil. Since our V6 has no

oil cooler, we're running it to higher rpm and

we're making more power, 225° F oil temperature

is not unusual and we see 250° on hot days at

high speed. Red Line gives us a needed

durability enhancement at those high temperature

levels. |

|

On our final day of waiting for the fuel pump,

we installed what we feel is the best shift

light for pod installations: Auto Meter's

Digital Pro Shift System (PN 3389). The "DPSS"

has a shift light, in seven colors which can be

selected by the user; five programmable shift

points and a digital RPM display. All the

programming is done by pushing the three, small

buttons on the gage's face. Simple programming

instructions are in the DPSS's manual. We put

the DPSS and a Sport-Comp II electric oil

temperature gauge (PN 3656), into an Auto Meter

pod (PN 10210) mounted on the THRS's left

A-pillar.

RPM data for the DPSS

came from the ignition module's low-resolution, engine

speed output, circuit #430, a purple/white wire going to

pin #8 of the ECM's blue connector. This is a critical

circuit. If there's a problem with it; the engine will

not run, so the splice needs to be soldered and properly

sealed.

|

|

|

|

The Auto Meter DPSS's

tach display is easy to read. Its LED

shift light is visible in bright

daylight and brilliantly intense at

night. In fact, after dark, most people

will use the DPSS's dimming feature. A

full-sweep, electric oil temperature

gauge and one of Auto Meter's

gauge pods for 4 Gen Camaro A-pillars

rounded-out our aftermarket

instrumentation. Image: CHpg Staff. |

|

|

|

|

We removed the oil filter

adapter, chucked it in a drill press,

drilled and tapped a hole for 1/8th-pipe

thread and installed the oil temperature

sender. Afterwards, thorough cleaning is

required. We installed the adapter with

a new oil filter adapter gasket and an

ACDelco PF-52 filter both from our Chevy

parts source, Tom Henry Racing. Image:

CHpg Staff. |

|

We passed on oil pan mounting for the oil

temperature sensor because it required pan

removal and welding. It was easier to remove the

oil filter mount, drill into its output side and

install the sensor there. Plus, that gave us a

chance to use a Standard Abrasives Porting Kit (PN

260001) to deburr and polish inside of the passage which

runs from the filter to the block's main oil

feed. |

We're Pumped

|

Our next THRS work session occurred right after

FeEx Ground kicked our

Racetronix shipment off the back of

their truck. Since we're eventually going to add

nitrous to the Tom Henry RS, we needed a pump

upgrade, anyway. The Racetronix High-Performance

Fuel System (PN W1-FPK-2) for '99-up V6 Camaros

fits the bill. It consists of a high-volume pump

assembly, the core of which is a Walbro 255

gerotor pump, and an auxiliary wiring harness.

The Racetronix's up-to-67 gal/hr. flow meets a

nitrous-injected engine's greater fuel

requirement with ease. |

|

|

The pump part of the

Racetronix High-Performance Fuel System.

For a sequence of photos illustrating

how to replace the stock fuel pump with

the Racetronix,

click

here. CHpg

Staff. |

|

The Racetronix supports

GM's "venturi feed" (prevents starvation at low fuel

levels), uses the production, plastic fuel feed tube

rather than a less-durable rubber replacement and stock

electrical connectors.

These pumps cause

voltage drop and increased heat in stock wiring due to

higher current draw. The solution is Racetronix's wiring

harness which includes 10-ga. wire, a relay and

stock-type connectors. It brings power directly from the

car's alternator back to the fuel pump and uses the

existing fuel pump power supply to run the relay. The

harness is assembled with soldered connections, is

inside O.E. split-loom and is accompanied by excellent

instructions. We wish all products like this were as

well-executed as the Racetronix Fuel System.

During the installation

of the Racetronix hardware, we disconnected the battery

and while we were there, decided to test it with our

shop's Auto Meter BT350 Battery and Electrical System

Tester. It's a computerized, hand-held, diagnostic

device which performs battery voltage and load, starter

draw, automated voltage drop and alternator tests. This

is a professional-grade device which test batteries with

CCA ratings of from 200-1600. It has digital display and

a memory which records the most recent 50 tests.

|

|

|

The Auto Meter battery

tester tells all. It determined that

what was originally a 690 CCA battery

now capable of only 400 CCA. Time for a

new battery. Image: CHpg Staff. |

|

Admittedly, the Auto

Meter is sort of expensive, but if you have a

fleet of cars like we do here at the Camaro Homepage,

being able to accurately test batteries and charging

systems avoids unnecessary purchases of batteries,

alternators or other charging system parts. According to

the BVA-350's display–just our luck–the project car's

original Delco battery tested as "weak". We yanked out

that old battery and dropped it off at Kragen Auto Parts

for recycling.

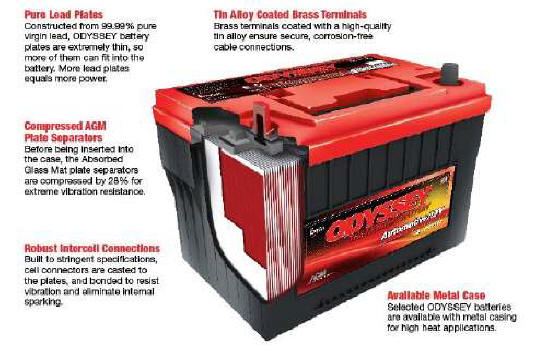

The best choice in

batteries for a performance car is the Odyssey, made by

EnerSys Energy Products in Missouri. Popular among

racers with high compression engines, car audio

enthusiasts, diesel pick-up owners, off-roaders whose

trucks have winches and those who will pay extra for a

battery with long service life, the Odyssey has earned a

solid reputation in the niche market that is premium car

batteries. Admittedly, an Odyssey battery is not cheap,

but they are a high-value product because of their

durability has them capable of outlasting just about

everything else on the market of comparable size and

cold cranking amp (CCA) rating.

|

|

|

An EnerSys Odyssey 75/86 battery. It

accepts either side or top connections. Image: EnerSys

Energy Products, Inc.

|

|

Some batteries provide

enormous cranking power–others, deep cycle reserve

power. EnerSys designs its products to do both. How so?

One reason are flat plates made of pure lead rather than

lead alloy. Pure lead plates can be made thinner, so

more of them fit into the battery. Lots of plates mean

more surface area and that means more power, up to two

times that of some conventional batteries.

Odysseys are capable of

providing five-second cranking pulses far in excess of

their CCA ratings and that's often, two-to-three times

the pulse rating of equally-sized conventional

batteries, even at low temperatures. Odyssey's can

handle deep cycles, too--as many as 400 charge-discharge

cycles to 80% discharge.

|

|

|

|

The 75/86 has a CCA

rating of 730-amp, a 5-sec. pulse hot

cranking amp rating of 1230 and a hot

cranking amp rating of 815. It's reserve

capacity is 100 minutes. Image: Image:

EnerSys Energy Products, Inc

|

|

Rugged construction,

Absorbed Glass Mat (AGM) design, vibration-resistant

welded, intercell connections and tough,

corrosion-resistant, tin-plated brass terminals combine

to give the Odyssey Battery reliability and durability

such that they have a 3-10 year service life. Further,

the AGM design prevents spills, even when installed on

its side. Unlike conventional batteries, Odysseys can be

stored for up to two years and still be returned to full

power.

|

The particular Odyssey

(PN PC1230DT) we put in the Tom Henry RS is a dual

terminal unit which EnerSys calls a "Group 75/86

battery". It has top terminals (typical of a 75) and the

side terminals (typical of an 86) used in GM cars from

the late-'60s to the mid-'00s. It's rated at 730 cold

(30-sec. at 0°F) cranking amps and 1230 "starting pulse"

amps (5-sec. at 68°F). This unit weighs 45.5 lbs, 10.2

lbs more than the O.E. Delco we took out. There are no

free lunches. The Odyssey's extra plates cost some mass,

but...we'll "loose it back" when we exchange the car's

stock, cast iron manifolds for headers.

|

|

|

|

The Odyssey quickly

installs in a Camaro. The integral

handle makes getting it in and out a

snap. Image: CHpg Staff. |

|

|

|

|

With a new fuel pump and a new battery,

it was time to take a break and drive to Goleta, a

seaside town in central California for a weekend away

from working cars. The THRS looks pretty snazzy with its

Fikse wheels. CHpg Staff.

|

|

|

|

The SLP grille looks much

better than the stocker, weighs about

the same and is a bolt-on. Image: CHpg

Staff. |

|

Looking at our Fikse Profil 5S wheels, we

decided the car's front view needed more visual

accent, so we ordered SLP Performance Part's

Replacement Grille (PN 50388). It's

injection-molded, has a gloss black finish and

carries a red Chevy Bowtie. It looks a heck of a

lot better than the stock piece. |

Next, we looked for

some twisties for action photos and to try out our new

wheels and tires. Compared to the 245/50ZR16s they

replaced, our 265/40ZR17 F1 Supercars put more rubber on

the road and have slightly less tread depth, so we

quickly confirmed an improvement in lateral grip and

steering response. In addition, the 17x9.5" Fikse

Profils were conspicuous in what they didn't do: degrade

handing with additional unsprung weight, in spite being

1.5" wider and an inch bigger in diameter.

|

|

|

Finally–a chance to run

The Tom Henry RS hard on some curvy

roads. Clearly, our numerous handling

enhancements made a significant

improvement. Image: Gary Peterson. |

With brake dust on the

wheels and dead bugs on the nose, the Tom Henry RS

needed washing. Fikse USA says to wash their wheels with

1:1, Simple Green and water. Then, we did the whole car

with another Simple Green product, "Car Wash". To keep

the Fikse's TechniPolished aluminum rims gleaming, we

treated them with Adam's Metal Polish #1 and #2.

The Heads-Up on Headers

While the Extrude Honed, stock exhaust manifolds

installed in Part Three improved flow on a per-manifold

basis, even after we had Extrude Hone AFM process them,

they had flow differences between each primary pipe. In

addition, the right manifold's #1 and #3 primaries

intersect at 90°. At minimum that would cause

turbulence at the junctions and turbulence causes

restriction. While Extrude Honed stock manifolds are

good if you're on a tight budget, because we wanted to

get the exhaust flow more consistent on a

cylinder-to-cylinder basis and nitrous oxide injection

increases exhaust flow; it was time to put headers on

because of their overall reduction in restriction and

more consistent cylinder-to-cylinder flow numbers.

|

|

|

Inside the right exhaust manifold in the

area circled is where we believe there is exhaust flow

turbulence and restriction. Image: CHpg Staff.

|

|

First, we researched off-shelf headers for the

V6 4th Gen F-car. RK Sport lists a header for

the 3800 but at the time we were preparing this

story, RK Sport told us that sales of that part

had not been real good and that once stock ran

out, it probably discontinue the product. Faced

with testing and covering a product which, going

forward, might not be available to readers; we

moved on. Pacesetter also markets a shorty

header for 3800s in Camaros, however, one part

number covers all '95s to '02s and we read

enough anecdotal accounts on the Internet of

98-02 V6 owners having difficulty with the EGR

connection on the left header that we decided

that product wasn't for us, either.

Clear Image Automotive makes a shorty header for

F-car 3800s that comes highly-recommended by

anecdotal accounts on the Internet, however, in

the pictures we saw on its web site, the left

header has the same problem as do the

Pacesetters–they won't bolt up to the 98-02 EGR.

An email inquiry to Clear Image for more

information went unanswered. |

There are some other

choices out there, such as the equal-length, 3-into-1

race headers from Force Fed Fabrications, however, they

require user fabrication of the connection to the rest

of the exhaust and, since this was not an all-out race

car and we needed a stock cat converter, Force Feds, as

good as they are, wouldn't work.

|

Confronted with one

header which will be discontinued and three others which

would require us to supply some level of fabrication

and/or modification to get them to fit the car, we

decided to accept an offer from Dawson Racing Headers to

prototype a set of bolt-on, shorty headers for 3800

Series IIs in '98-'02 Camaros using our project car.

|

|

|

|

Next to go on

the Tom Henry RS was a set of

custom-built exhaust headers from Dawson

Racing Headers. Image: CHpg Staff. For a

photo story about how headers are made,

Click Here

|

|

Dawson

Headers, in Nuevo, California, was owned by former

Hooker Headers engineer, Tom Dawson. The company had 20

years of experience and did premium headers for

everything from Top Fuel cars to tractor-pullers,

including Camaros–all of 'em, from '67 to '02 and

'10-up, street or race, and with just about any engine.

|

|

|

With Dawson Headers and

1.8 rockers installed, it was once

again, onto the Superflow chassis dyno

at Westech Performance Group to validate

the work done to date. |

|

Our Dawsons

are a shorty design. Their oxygen sensor bungs are in

stock locations. The headers are designed with easy

access to header bolts and the Denso IT-20 spark plugs

we like to use. The connection on the left header's #1

primary pipe is configured to bolt-up to the '98'-02 EGR

plumbing.

The mounting

flanges are 3/8-inch, laser-cut, mild steel. The primary

pipes 1 5/8-in. diameter, 16-ga. (.065" wall), 1010 mild

steel tube stock. All curved sections are are mandrel

bent. Most joints are tungsten inert gas (TIG) welded,

however, typical of high-end race headers, the outside

of each pipe-to-flange joint is TIG, silicon-bronze

brazed. The collectors are 2.5-in diameter 16-ga. mild

steel. The Dawson Racing Headers' system for a 3800

Camaro includes a 2.5"-into-3" y-pipe with a bolt-up

connection which must be welded on the stock catalytic

converter.

Sadly, on

Jan. 24, 2009, a couple of years after he did the

headers on the Tom Henry RS, Tom Dawson died of

complications due to diabetes and kidney problems. Tom

was astonishingly good when it came to designing and

building headers. He could look at an engine, take a

piece of tubing cut and bend it and it would fit

perfectly. Tom will be missed. He was a big guy with a

big heart and one hell of an artist with a tubing bender

and a welder.

Once the

headers were complete, we sent them to Extreme

Performance Coatings to be treated with the company's

ceramic-chrome exterior coating and its "MCS" interior

insulating coating. Extreme Performance uses coating

materials from one most innovative and well-established

suppliers in the industry, Techline Coatings.

First, the

headers are aluminum-oxide grit-blasted then washed. The

outside treatment is fairly basic: a ceramic-metallic

coating is applied with conventional equipment. What's

unique is the proprietary process Extreme uses to coat

the interior of a set of headers with a thermal

insulating compound. After the outside and the inside

are done, the parts are baked to cure the coatings.

The idea

behind the coating is to keep the exhaust heat in the

headers such that cat light-off doesn't become a problem

and the amount of heat radiated to the vehicle interior

decreases. Extreme's MCS inside pipe insulating coating

is the first barrier and the ceramic-chrome exterior

coating is the second.

We installed

the Extreme-coated, Dawson Headers using Fel-Pro

gaskets, new Denso oxygen sensors (PN 234-4018) and

Stage 8 Locking Fasteners.

Finally, the

THRS Team met at Westech Performance Group for another

chassis dyno session. First, Z-Industries,' Drew Zimmer,

updated our computer programming, then we tested the

Whisper Motorsports air box lid we installed in Part 3,

using a stock air box fitted with a Green Filter as a

baseline. Then, we switched to the Whisper Motorsports

carbon fiber air box lid with the Green Filter and

gained an additional 2-hp at peak power and 5-lb/ft at

peak torque.

|

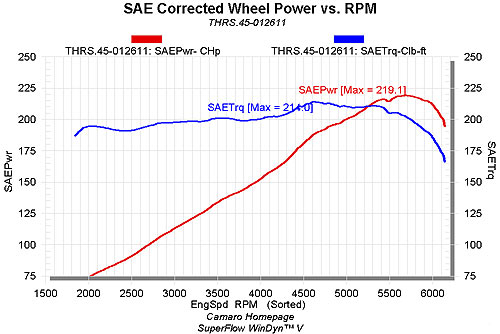

With the

Whisper Lid in place, at the rear wheels, the Tom Henry

RS peaked at 219.1 SAE horsepower at 5700 rpm and 214.0

pound/feet torque at 4600 rpm. Figuring 18% driveline

loss that's 267-hp SAE at the flywheel, 17-hp more than

our original goal of 250 and 70-hp more than stock. Not

only is that an improvement–13-hp–over the last test in

Pt. 3 (to see that data, click here), but that peak

moved higher and the power curve extended to about

200-hp@6100 rpm whereas before, it dropped-off past

5500. From a drivability standpoint, for a V6, the Tom

Henry RS is a stump puller on the street with a fat

torque curve which is above 190 lbs/ft from 1900-6200

rpm. No doubt–Dawson Racing Headers along with all our

other mods work very well! |

|

|

|

This is the Whisper Lid as installed on

the THRS. This replaced an SLP lid designed for a V8

which leaked around the filter and required some complex

ducting to the engine. Image: CHpg Staff.

|

|

While the

car did make almost 220-hp, we noticed a little dip in

the numbers right before peak power. We were running the

car on pump gas and attributed the dip to some

detonation and ensuing knock retard. In the last part of

the series we had trouble with KR but this time, it was

coming at a different point in the power curve. We added

three gallons of Rockett Brand 100 octane Racing

Gasoline, then ran again, and the "KR" was gone. We made

220-hp.

|

|

|

The latest dyno data has us pretty

happy, actually–were ecstatic! Power is

up. We up 15-hp from last time with most

of that coming at high rpm. Torque has

improved, not only the peak, but the

whole torque curve as flattened

considerably since our last test. The

rpm range of the engine has extended

somewhat, too.

|

|

In Part 5,

we have a few more small intake and exhaust tweaks up

our sleeves. We'll, also tell you a little more about

details of the THRS's engine controls calibration. We'll

do some more suspension work and we'll overhaul the

brakes.

Sources:

|

Daniel Stern Lighting, Inc.

2101-35 High Park Ave.

Toronto, ON, M6P 2R6

866-861-8668

www.danielsternlighting.com |

Rockauto

www,rockauto.com |

Denso Sales

of California, Inc.

3900 Via Oro Av.

Long Beach CA 90810

310.513.8582

www.densoaftermarket.com |

Design Engineering, inc.

604 Moore Rd.

Avon Lake OH 44012-2315

800-264-9472

www.designengineering.com |

Eastwood Company

263 Shoemaker Road

Pottstown PA

19464

www.eastwoodco.com |

EnerSys Energy Products,

Inc. (Odyssey Battery)

617 North Ridgeview Dr.

660.429.2165

www.odysseyfactory.com

|

Extreme Performance Heat

Coatings

515 N. Elevar St.

Oxnard CA 93010

805.485 2667

www.xtremeperformanceheatcoatings.com |

Fikse USA, Inc

6851 S 220th St

Kent, WA 98032

253.872.3888 |

Global West Suspension

Systems

655 S. Lincoln Av.

San Bernardino CA 92408

877.470.2975

www.globalwestsuspensionc.om |

Goodyear Tire and Rubber Co.

see your local Goodyear dealer

www.goodyeartires.com |

Helm,

Inc. (GM Service Manuals)

14310 Hamilton Ave.

Highland Park, MI 48203

800 782 4356

www.helminc.com |

|

Katech,

Inc.

24324 Sorrentino Ct.

Clinton Twp MI 48035

586.791.4120

www.katechengines.com |

Mac Tools

Suite 200

505 North Cleveland Avenue

Westerville OH 43082

800.mac.tool

www.mactools.com |

Quality Auto Service

3460 Falcon St.

Pomona CA 91767

909.596.5502 |

Racetronix

locate dealers at:

www.racetronix.com |

Red Line Synthetic Oil Corporation

6100 Egret Court

Benicia CA 94510

800.624.7958

www.redlineoil.com |

Rockett Brand Racing Fuel

3703 W. Lake Avenue, Suite 75

Glenview IL 60026

800.345.0076

www.rockettbrand.com |

Standard Abrasives Motorsports Division

4201 Guardian St.

Simi Valley CA 93063

800.423.5444

www.sa-motorsports.com |

Tom Henry Racing

Box 68

Bakerstown PA 15007

877.842.4389

www.tomhenryracing.com |

Tucker Tire Service Co.

612 N Azusa

Covina CA 91722

626.331.0663

www.tuckertirecompany.com |

Vericom Computers

Suite 200

14320 James Road

Rogers MN 55374

800.533.5547

www.vericomcomputers.com |

WeatherTech Automotive Accessories

5230 Walnut Ave.

Downers Grove IL 60515

800.441.6287

www.weathertech.com |

Westech Performance Group

Unit C

11098 Venture Av.

Mira Loma CA 91752

951.685.4767

www.westechperformance.com |

Whisper Motorsports

Suite 305

4400 118th Av. North

Clearwater FL 33762

727.573.1292

www.whispermotorsports.com |

Yella Terra USA

1935 Tommy Webb Dr.

Meridian MS 39307

601 485-3355

www.yellaterra.com.au |

Z-Industries

31200 Santiago Rd.

Temecula CA 92592

951.303.6857

www.z-industries.com |

Return

to Project Index Click Here

|